Make It Pop Like Champagne

Printing techniques to make your holiday print designs pop in all the right ways.

While we’re on the subject of Christmas in July, can I just say that the holiday season brings out some of the most elegant print designs we see all year long! If you’re anything like me, you find yourself standing at the mailbox swooning over beautiful designs featuring specialty printing techniques while trying to figure out “how did they do that?”

Because I’m convinced I’m not the only one, I thought I’d offer a quick overview of some popular printing techniques you might want to see play into your card concept this year. Knowing a little more about these processes may inspire an idea for creating a fabulous holiday design concept. It may also inspire you to get started sooner than later because beautiful design and printing techniques don’t happen overnight! Take a look at these techniques.

SPOT UV

Spot UV is a clear coating that covers a set part of the design adding a pop effect to your print. This technique can add a subtle texture or shine to your prints or can help some bright colored designed really leap off the page. It’s fantastic for creating tone on tone effects with pattern and/or text or just adding a little luster in specific spots.

Spot UV & Silver Foil

Chris Hughes

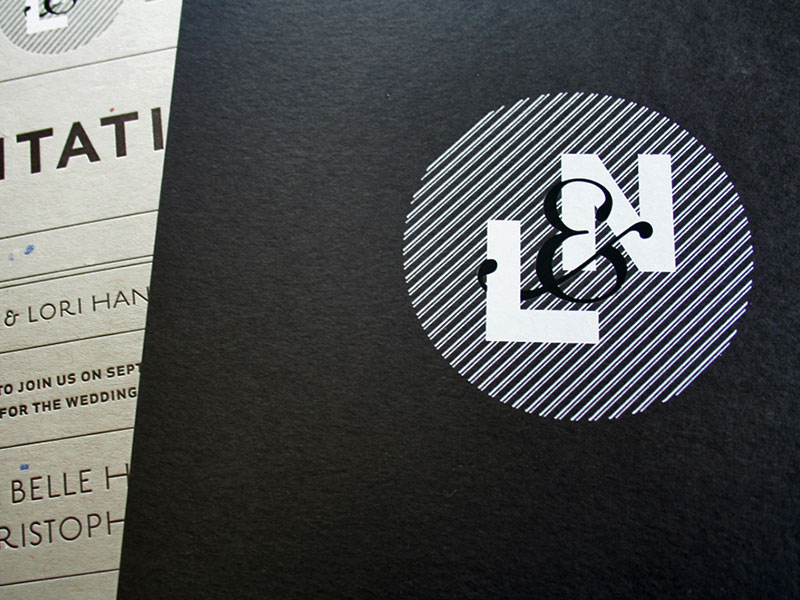

FOIL STAMPING

Typically, when people hear the word foil stamping, they immediately think of the shiny gold, silver, rose gold, or copper colors. However, there are so many options when it comes to foil stamping. Yes, there are lots of different types of metallic foils, both high shine and some more dull and brassy, but there are also solid flat colors that people sometimes forget about. This comes in handy when you want white or light color text to pop of a dark or black colored paper.

Letterpress on white side & White Foil on black

Ned Wright and Laura Belle

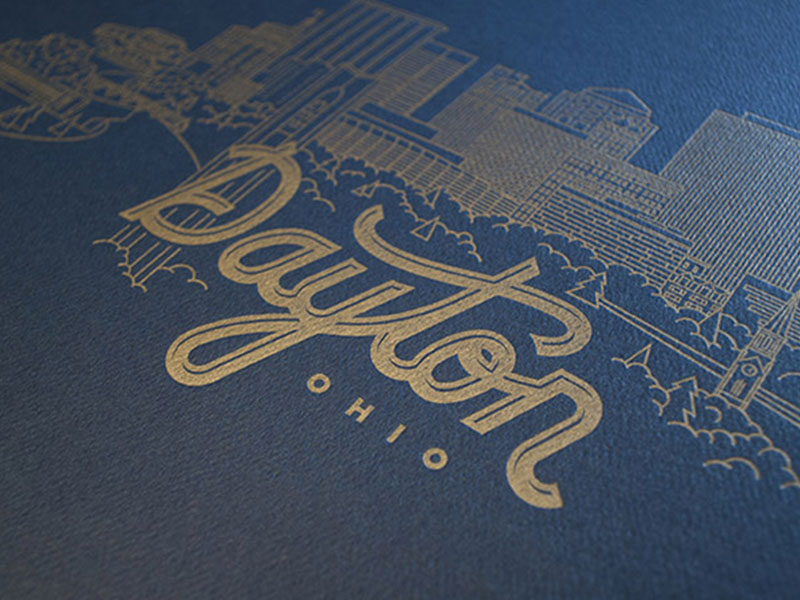

METALLIC INK

Foil stamping can be pricey depending on the foil color and die that you are using. However, metallic ink can be a great substitute when you need to keep costs down but want to add a hint of sparkle to your design. The great thing about metallic ink is that it can be printed on a various types of paper, such as rich cotton, colored paper, or coated paper, where some other specialty printing techniques limit you on the type of paper that can be used. Metallic ink comes in practically every color of the rainbow. So, let your imagination run!

Metallic Ink on navy blue paper

Andrew Althouse

EMBOSS & DEBOSS

Embossing or debossing gives print design a tactile feel. Texture encourages the recipient to feel the card, finding all the grooves that the design holds. (Warning: it might cause ooh’s and ahh’s to escape your mouth). Embossing raises design or letters on the paper (the design is pressed from the back side of the paper). Debossing presses the design into the paper (from the top of the card). Both techniques can be used with color-filled design or can be embossed without color (a.k.a. blind embossed). These techniques sometimes limit which papers can be used to make sure that the designs come out clean and clear. Be sure to specify paper accordingly.

Blind Emboss

George Gozum

DIE CUTTING

Die cuts are a fun way create a ‘reveal’ or create a new shape for a card design. Die cutting is a process that uses a “die” to cut shapes into a print. This can also add more unique edge designs to your cards. Die cutting is kind of like cutting out holiday sugar cookies with a cookie cutter. One thing to keep in mind when incorporating a die cut is that this process can sometimes take a little longer to produce. So allow plenty of time and rest assured the final outcome is always worth the wait. The possibilities are endless!

Custom Die Cut

Xavier Correa

And last but certainly not least…

LETTERPRESS

Letterpressing has become a very popular in the past few years for printers, but this technique is far from new. It is the oldest form of printing that inadvertently adds another layer/level to your prints. Due to the process, letterpress requires a thicker card stock to allow for impressions to be made and a more tactile paper that will hold the ink. Letterpressing also needs more production time since each of the color imprints will be printed individually instead of multiple prints stacked on a large sheet and then cut down to size. This technique really encourages people to touch your card since a natural, subtle deboss happens when the designs are printed onto the cards.

Letterpress

Brightspot Creative

Now that you have knowledge of some of the popular printing techniques, dreaming up an exciting design idea should be a snap. Don’t forget about all the logistics to actually get that beautiful card produced and sent! Download BrightSpot’s holiday card productions schedule below to keep you on track.

And if you want to collaborate or even turn the whole thing over to an expert team, give us a call. We love to brand the holidays!